VarmintAl did a series of calculations by using LS-DYNA, a well-established finite element code for exploring dynamic behavior of the bolt and case during a shot. One series of calculations looked at case head expansion.

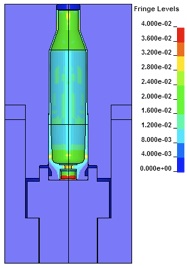

Cross-section of case in typical .243 Winchester chamber showing fringes of plastic strain at the peak pressure of 57,400 psi.

He applied a typical chamber pressure-time history to the inside of a cartridge case in a rifle chamber with the bolt in place. The pressure pushes the case back on the bolt face so the only way the brass can go is out where its diameter is smaller than the chamber. Our attention is on the small length of the case head just above the extraction groove.

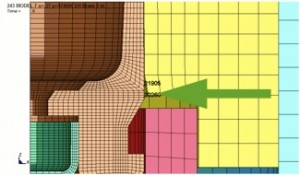

The green arrow is about where VarmintAl tracked the expansion. This area has the most brass and is not supported by the case wall. Expansion at this location is a rough analog to crush cylinder behavior.

You can see from the illustration that the case head is not supported here. The lack of support allows the brass to expand in response to the dynamic pressure inside the case. Fortunately our safe loads are designed so that this expansion is not readily seen by the naked eye. Indeed, if you can see it, you have dangerously high pressures!

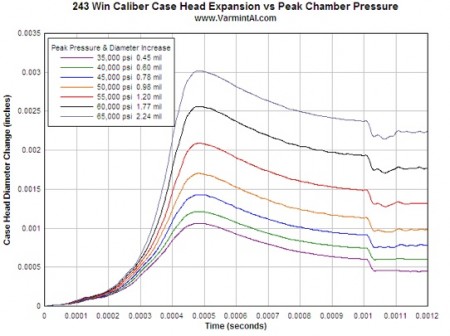

The head expands first elastically, meaning that, for very low pressures, the case head returns to the original diameter. As the pressure increases, however, we get plastic strain on top of the elastic, resulting in a permanent change of diameter. The amount the head expands depends both on the magnitude and duration of the pressure above the brass yield strength. We use precision calipers to measure this tiny residual change in diameter since we can’t see it.

Time histories of case head diamter for a .243 Winchester for various peak pressures.

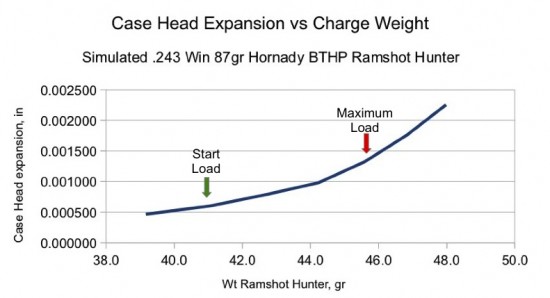

The calculated permanent set is the residual strain seen at the right-hand side of the time history plot. QuickLoad was used to determine how much Ramshot Hunter™ would be needed to get VarmintAl’s peak pressures for a typical bullet in the .243 Winchester. Then the permanent set of the results shown above was plotted against the powder needed to get the peak pressure. The permanent set as a function of powder charge is shown in the scatter plot.

The starting load for this powder and bullet combination is 41.0 grains per the Ramshot Load Guide Edition 4.4© while the maximum load is shown as 45.5 grains of Hunter™. The start load appears to be in a region where not much plasticity happens. The maximum load appears to have enough pressure that the brass is starting to move more rapidly suggesting significant reductions in case life and safety when more than the maximum recommended amount of powder is used.

Simulated trend line for case head expansion.

Plot YOUR own trend line even though some handloaders use 1 mil for 30-30 pressures and 1.5 mil for modern rifles. This way you will have data relevant for YOUR rifle and brass!

Using fired cases for this exercise is a losing proposition because expansion from previous shots work hardens the brass, giving less expansion for the same pressure levels. Also note that the factory reference loads are just that: reference loads. The baseline works when the brass hardness is the same for both them and your brass.

There is no guarantee, however, that the factory loads will have the same brass as your unfired brass, but it is the closest we can get. The uncertainty underscores the reason for looking at a series of charge weights – we are looking for the region where the brass flow accelerates as a back-up to getting the same strain as the factory load.

Acknowledgements

The author is deeply indebted to VarmintAl.com for significant constructive criticism and for giving permisson the results of a calculation that is a rather strong example of why the method can work as well as Craig Eagle, Dick Hatfield, Greg Luli, Paul Scott and Todd Slavic for critical reviews. These reviews enabled the writing of a more readable and complete discussion.

1Review this pdf for a description of the ladder test: http://www.desertsharpshooters.com/manuals/incredload.pdf

2 Many wildcat cartridges need to be fireformed to be useable. Once-fired brass may be useful in this event provided that the one uses the same recipe is used when forming the brass to be used in this testing.

Leave a Reply

You must be logged in to post a comment.